CHIRON Group continues to grow

10日 五月 2023

Capacities expanded, global presence strengthened, range of products and services extended

The CHIRON Group continued growing in the 2022 business year despite the enduring difficult market conditions, as CEO Carsten Liske explained: „The positive trend in order intake has continued based on our technology leadership in vertical milling and mill-turning as well as our innovative and further completed product portfolio.“

Trend for 2022: increased again

The company recorded a clear rise in order intake last year and the CHIRON Group was also able to significantly increase its turnover. According to CSO Bernd Hilgarth, the Medical and Precision technology business segment developed strongly: „Order intake in Medical and Precision was very positive, as has been the case in previous years.“ Automotive remained constant thanks to growth in the e-mobility segment, while Aerospace recovered and is on the up again. Bernd Hilgarth summed up the figures: „Overall, we are more broadly positioned than previously thanks to growth on different markets, making us more resilient to fluctuations or changes in individual segments.“

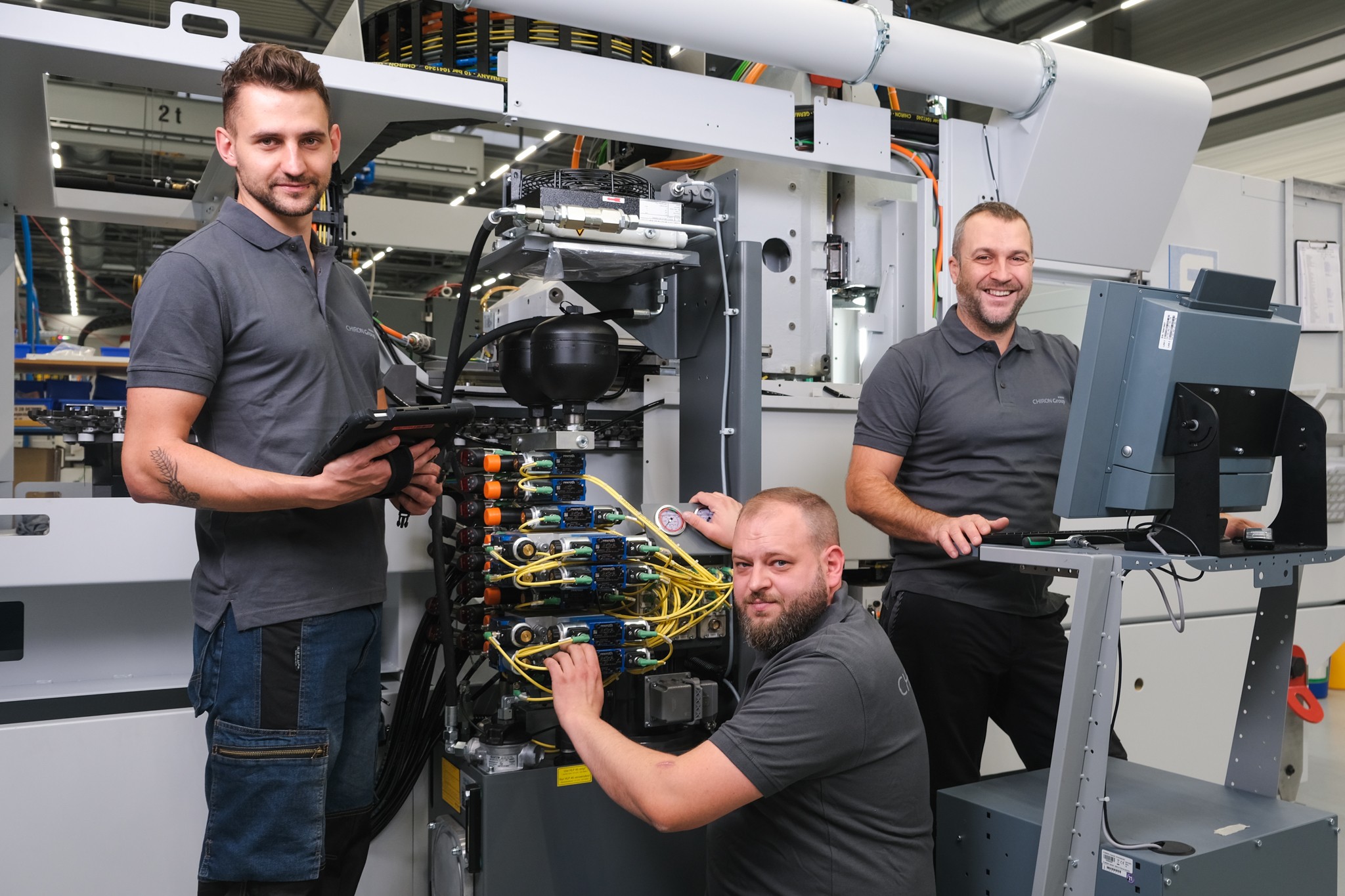

Expansion of capacities, global presence and expertise

To meet growing demand and serve customers even more effectively in their markets, the CHIRON Group made significant investments last year. The company has been present in Eastern Europe since August through a new location, CHIRON Croatia; the portfolio now also includes high-speed motor spindles, clamping devices, and spindle services. Construction of a new production hall measuring roughly 1,000 square meters is to begin soon at the Zadar site.

CHIRON Swiss in Isérables is now a fully-fledged sales and service company for the entire product portfolio of the CHIRON Group in the Swiss market. Series production of the Micro5 machining center and the new Feed5 automation has been underway in Tuttlingen, Germany since October – on an assembly line specifically designed for the smallest machining center produced by the CHIRON Group. In addition, capacity for the end assembly of series was developed at CHIRON Polska and the personnel was qualified accordingly.

The integration of Greidenweis GmbH, which was acquired in January 2022, was completed successfully. With its combined expertise, the CHIRON Group can convincingly meet the growing demand for automating complete processes. This applies to process automation applications ranging from high-volume parts production in a single machining center to complex production lines, where automation ranges from blanking to end-of-line testing.

Sustainability as a strategic model for success

As Carsten Liske explained: „With the global strategy program ,Sustainability@CHIRON Group‘ the Chiron Group has laid a solid foundation for making sustainability a strategic factor in our business model, for us and our customers. We are building on this and continuing with this approach – to make the CHIRON Group carbon-neutral and, just as importantly, successful in the long term.“ The first sub-goal toward achieving net zero emissions globally in production by 2025 was reached in December 2022: Production in Germany (Scope 1 and 2) is carbon-neutral and both the Taicang Innovation Factory and Croatian site at Zadar will also reach this goal this year. In addition, under the Science-Based-Target Initiative (SBTi) the company has committed to playing its part in achieving the goals of the Paris Agreement on climate change. As CTO Dr. Claus Eppler says: „We are one of the first companies in our industry to collaborate with the SBTi. This shows just how seriously we take sustainability.“ A visible symbol of this is the first sustainability report for 2021. In the report, titled „SUSTAINABILITY by Performance and Precision“, the company presents its strategy, provides data on past successes and informs about its activities in all relevant fields.

Sustainability and impressive environmental performance are also reflected in the portfolio. One example is multi-spindle systems, which give customers a competitive edge thanks to reduced investment costs, lower space requirements and reduced energy consumption.

Outlook and aspiration

CEO Carsten Liske anticipates the positive trend will continue in 2023: „We are successful, but we want to be the best in the markets that are relevant to us. We are striving relentlessly to gain market share, to better develop the potential among existing customers with our product and, in particular, our service portfolio, and to win new customers.“ To achieve these ambitious goals, the number of employees is set to rise again. Carsten Liske is optimistic in this respect too, despite the shortage of skilled workers: „In Tuttlingen, we have had a strong year since September with 32 young talents. In addition, a survey by stern and Statista shows we are one of ,Germany's best employers 2023‘ and we are listed as one of the 500 global market leaders for 2023 by WirtschaftsWoche thanks to our special expertise in ,CNC-controlled, vertical machining and turning centers‘. This recognition, among other awards, reflects our innovative strength and corporate culture and make us attractive to new skilled workers.“

About the CHIRON Group

The CHIRON Group, headquartered in Tuttlingen, Germany is a global company specializing in CNC vertical milling and mill-turn machining centers, as well as turnkey and automation solutions. Comprehensive services, digital solutions and products for additive manufacturing complete the portfolio. The Group has a global presence, with production and development sites, sales and service subsidiaries, and sales agencies worldwide. Around two thirds of machines and solutions that are sold are exported. Key customer sectors are the automotive, mechanical engineering, medicine and precision engineering, aerospace industries, as well as tool manufacturing.

The CHIRON Group is proprietor of the CHIRON, STAMA and FACTORY5 brands for new machines, as well as the automation brand GREIDENWEIS, CMS for refurbishment and HSTEC for motor spindles and fixtures. CHIRON machining centers are renowned for their highly dynamic design and their precision. The focus of STAMA is on stability and complete machining, while FACTORY5 expert area is high-speed machining of micro-technical components. GREIDENWEIS is a system partner for custom, end-to-end automation solutions, and CMS provides completely refurbished machines from the Group. HSTEC specializes in the development, manufacture and repair of high-speed motor spindles and fixtures. The final core area of expertise in the CHIRON Group is in additive manufacturing products and solutions.

Contact person for editors:

CHIRON Group SE

Christina Messmer

Kreuzstraße 75, 78532 Tuttlingen, Germany

Phone: +49 7461 940-3712